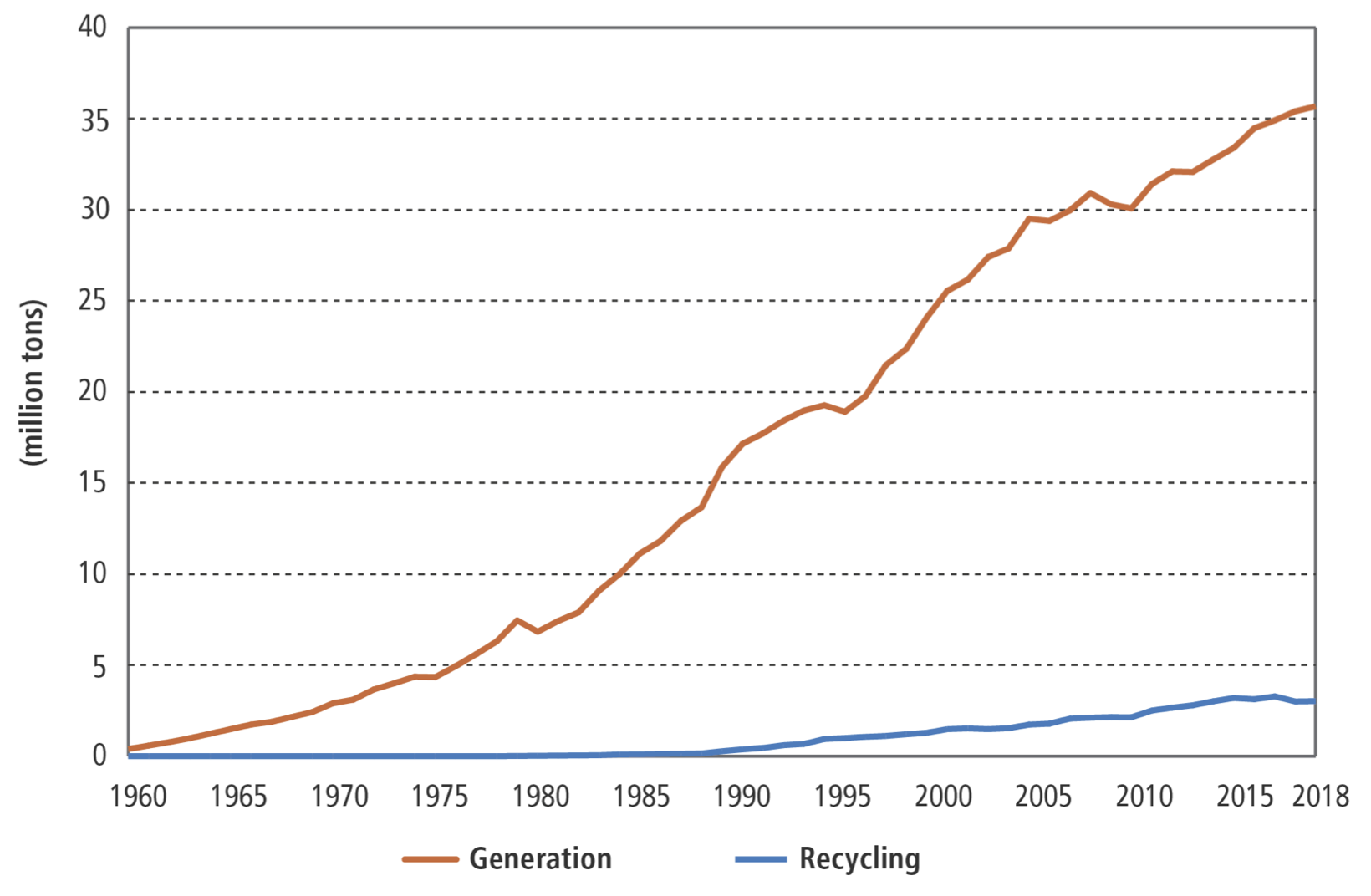

For decades, we’ve been told that recycling is the answer to our plastic problem. But while recycling rates have stayed at 5%, plastic production has exploded.

Each year, the world produces more plastic than ever before — and most of it is designed for single use. From food packaging to online orders, we keep adding more plastic to the system than it can possibly handle.

Even if recycling worked perfectly, it couldn’t keep up with how fast we’re making new plastic.

This growth is driven by convenience and consumption — products made to be quick, disposable, and cheap.

That’s why the recycling system keeps breaking:

it was never built for an infinite stream of new plastic.

It’s a linear model in a world that needs circular solutions.

The result: far more new plastic is produced each year than recycled plastic.

How We Turn Waste into Treasure

Step 1 - Collect

We take polypropylene (PP) - the kind most curbside recycling programs can’t handle -

comes from households (like food containers, yogurt tubs) and hospitals as clean medical waste.

Step 2 - Sort

Each piece is thoroughly inspected and washed if it has grease or residue.

Then it’s sorted by color and type.

Step 3 - Shred

The plastics are fed into a shredding machine that cuts them into small flakes, making them easier to melt and repurpose into new forms.

Step 4 - Mold

We choose color combinations and load the shredded plastic into the injection machine, where it’s heated to around 185°C for several minutes.

Once melted, the mix is injected into the mold to take its new shape.

Step 5 - Release

Once the mold cools, it’s released to reveal the finished piece.

Edges are smoothed by hand, but never sanded to avoid creating microplastics.

Step 6 - Reuse

Each piece is made to be used again and again — keeping waste out of landfill and reminding us that plastic can have more than one life.

Shop Reusable Name Tags

Reusable name tags made from 100% recycled plastic